-

[0] Panier de soumission

- Se connecter

- Votre requête par fichier

- Soumission pour produit non trouvé

Mon panier de soumission - Soumission rapide

-

Catégories de produits

- Attaches industrielles Attaches industrielles

- Composantes d'outillage Composantes d'outillage

- Goupilles de verrouillage à billes Goupilles de verrouillage à billes

-

Éléments de repérage

Éléments de repérage

Éléments de repérage

- Dispositifs à ressort

- Mordants

- Goupilles d'alignement

- Goupilles d'expansion

- Vérins de gabarit ajustables

- Guides de positionnement

- Pieds d'appui

- Supports de gabarit

- Supports de gabarit rallongés

- Goupilles de centrage

- Boutons d'appui

- Goupilles cylindriques rectifiées

- Rest Pads

- Tooling Balls & Covers

- Vis de calage ajustable

- Work Support Jacks & Risers

- Technologies de bridage Technologies de bridage

- Solutions de levage Solutions de levage

- Boutons, Poignées, manivelles, leviers et volants Boutons, Poignées, manivelles, leviers et volants

-

Canons de perçage (Drill Bushings)

Canons de perçage (Drill Bushings)

Canons de perçage (Drill Bushings)

- Canons de perçage d'alignement

- Canons de perçage amovibles

- Canons de perçage encastrables

- Canons pour perçeuse - Gun Drill Bushings

- Canons à rainures pour lubrifiant

- Canons de perçage à paroi extra mince

- Canon pour perçage pneumatique - TYPE AF

- Canons de perçage de gabarit - Template Bushings

- Canons porte outils

- Canons de percage en nitrure de titane (TiN)

- Canons de perçage en carbure de tungstène

- Canons pour carte de circuits imprimés - Type CB

- Canons EZ Cast

- Manchons Oilite® Bushings

- Accessoires de canons de perçage

- Quincailleries Industrielles Quincailleries Industrielles

- Fournitures industrielles Fournitures industrielles

- Système de boyaux modulaires Système de boyaux modulaires

- Liquidation Liquidation

- Catalogue

-

Catégories de produits

- Attaches industrielles Attaches industrielles

- Composantes d'outillage Composantes d'outillage

- Goupilles de verrouillage à billes Goupilles de verrouillage à billes

-

Éléments de repérage

Éléments de repérage

Éléments de repérage

- Dispositifs à ressort

- Mordants

- Goupilles d'alignement

- Goupilles d'expansion

- Vérins de gabarit ajustables

- Guides de positionnement

- Pieds d'appui

- Supports de gabarit

- Supports de gabarit rallongés

- Goupilles de centrage

- Boutons d'appui

- Goupilles cylindriques rectifiées

- Rest Pads

- Tooling Balls & Covers

- Vis de calage ajustable

- Work Support Jacks & Risers

- Technologies de bridage Technologies de bridage

- Solutions de levage Solutions de levage

- Boutons, Poignées, manivelles, leviers et volants Boutons, Poignées, manivelles, leviers et volants

-

Canons de perçage (Drill Bushings)

Canons de perçage (Drill Bushings)

Canons de perçage (Drill Bushings)

- Canons de perçage d'alignement

- Canons de perçage amovibles

- Canons de perçage encastrables

- Canons pour perçeuse - Gun Drill Bushings

- Canons à rainures pour lubrifiant

- Canons de perçage à paroi extra mince

- Canon pour perçage pneumatique - TYPE AF

- Canons de perçage de gabarit - Template Bushings

- Canons porte outils

- Canons de percage en nitrure de titane (TiN)

- Canons de perçage en carbure de tungstène

- Canons pour carte de circuits imprimés - Type CB

- Canons EZ Cast

- Manchons Oilite® Bushings

- Accessoires de canons de perçage

- Quincailleries Industrielles Quincailleries Industrielles

- Fournitures industrielles Fournitures industrielles

- Système de boyaux modulaires Système de boyaux modulaires

- Liquidation Liquidation

- Accueil>

- Catalogue>

- Composantes d'outillage>

- Technologies de changement rapide de gabarits>

- Système Ball Lock®

Système Ball Lock®

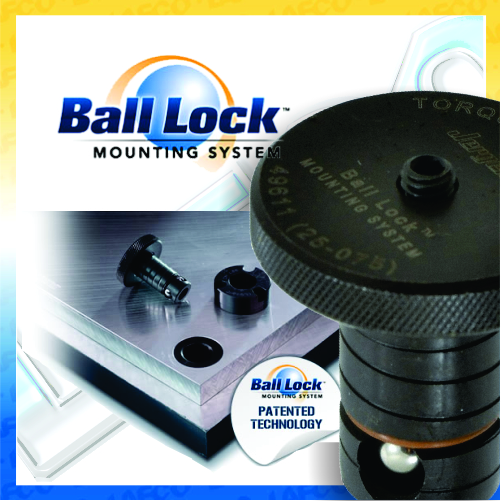

Inside the shank are 3 balls that expand into a tapered groove in the receiver bushing. This action draws the plates together. The locking balls are activated by turning a setscrew in the head of the shank, which pushes a 4th ball to evenly distribute the clamping forces between the 3 locking balls. No more dowel pins or cap screws, and no need to search around for a hex wrench to remove Ball Lock® shanks.

Benefits:

- Incredibly FAST setups and changeover

- Powerfully strong holding forces

- Combines locking and locating in the same motion

- Eliminates the need for indicating on CNC machines

- Repeatability of +/-0.0005” (+/-0.013mm) or better

Ball Lock® is the original and most widely used quick change fixture system available. Ball Lock® can be your competitive edge…just like thousands of other shops across the country.